Fully Customizable Cold Storage Racking by JULI®

Tailor every detail—dimensions, load capacity, shelving type, and color—to meet your cold storage requirements and maximize warehouse efficiency.

Cold Storage Racking — Efficient Solution for Cold Chain Warehousing

JULI® Cold Storage Racking is a high-strength, durable storage system specially designed for cold chain logistics, refrigerated warehouses, and low-temperature manufacturing environments. This racking solution helps maximize storage density, improve space utilization, and ensure reliable performance under extreme temperature conditions.

All specifications—including dimensions, load capacity, shelving configuration, and safety features—are fully customizable to meet your unique operational requirements

| Specification | Typical Value | Customizable |

|---|---|---|

| External Dimensions | 1320 × 1250 × 1500 mm |  Length, Width, Height Length, Width, Height |

| Internal Dimensions | 1200 × 1200 × 1300 mm |  Based on product size Based on product size |

| Load Capacity | 1500 kg / 2000 kg |  Up to 3000 kg+ Up to 3000 kg+ |

| Stacking Height | Max. 4 layers |  Site-specific Site-specific |

| Steel Material | Q235 / Hot-rolled Steel |  Optional grades Optional grades |

| Surface Finish | Powder-coated / Galvanized |  Anti-rust / Cold room safe Anti-rust / Cold room safe |

| Racking Style | Upright / Inverted / With guards |  Full customization Full customization |

| Temperature Resistance | -30 °C to +40 °C |  Cold storage rated Cold storage rated |

| Safety Features | Guard rails, mesh panels, ball locks Etc. |  As required As required |

Customizable Rack Styles

Custom design adjustments, safety enhancements, and structural reinforcements are available upon request. We offer a variety of standard and customized options, including the following commonly used configurations:

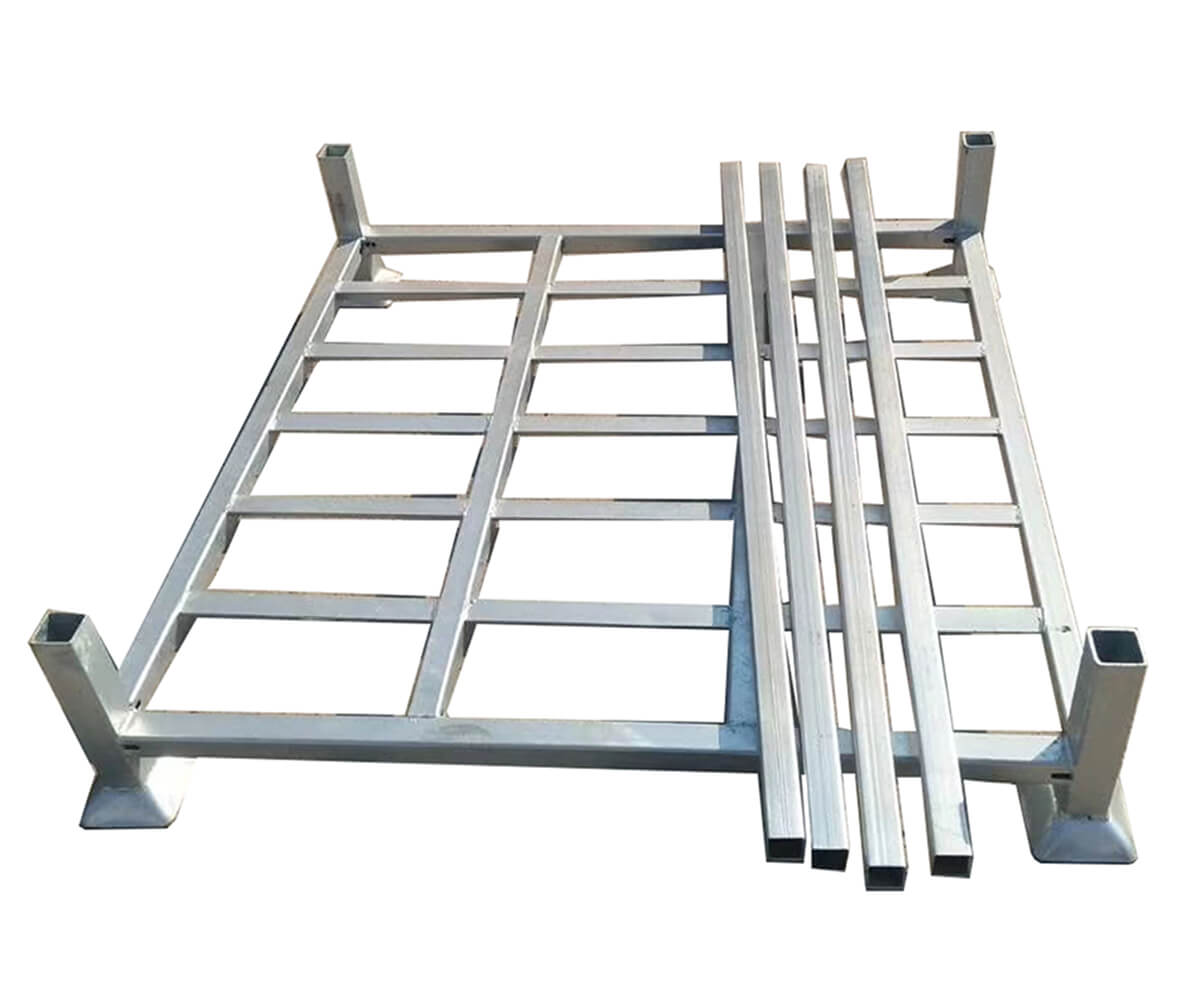

Square Tube Post Racking

Round Tube Post Racking

Galvanized square tube shelves

Inverted Nestable Racking

Upright Nestable Racking

Galvanized Nestable Racking

Tiered Nestable Racking

Guardrail Nestable Racking

Key Features & Benefits

Fully Customizable: Tailor every detail—dimensions, color, capacity, safety features—to match your unique application.

Cold Chain Ready: Built with corrosion-resistant steel and coatings for durability in freezing environments.

High Load Capacity: Supports up to 2,000 kg with certified structural integrity.

Space Efficiency: Nestable design allows compact storage when not in use; ideal for dynamic storage cycles.

Safe & Secure: Optional mesh, rails, and barriers protect workers and goods.

Why Choose JULI® Cold Storage Racking?

Space Optimization

Engineered to maximize vertical and horizontal storage capacity in cold warehouses.

Cold Chain Performance

Designed to withstand low-temperature environments with corrosion-resistant finishes.

Heavy-Duty Load Capacity

Supports loads up to 2000 kg with stable, reinforced racking structures.

Fully Customizable

Dimensions, load ratings, shelving types, and colors can be tailored to your specific needs.

Easy Installation & Handling

Simple assembly and flexible configuration ensure efficient warehouse operations.

Trusted Quality

Manufactured by JULI® — a reliable partner for global cold chain logistics solutions.

Frequently Asked Questions (FAQs)

Cold storage racking systems are engineered to handle heavy loads, with standard pallet racking typically supporting up to 2,000 lb (≈900 kg) per level. For high-density warehouses, JULI® provides fully customized solutions with reinforced steel structures capable of supporting even greater capacities to meet demanding cold chain requirements.

In refrigerated or frozen storage facilities, anchoring bolts must remain reliable despite extreme temperatures. Mechanical expansion anchors are often recommended because chemical anchors may not cure properly in subzero conditions. JULI® designs racking systems with anchoring solutions tailored to the unique flooring and temperature requirements of each cold storage warehouse.

Cold storage racking must resist condensation, frost, and humidity that can accelerate rust. The most effective solutions include galvanized steel, powder-coated finishes, or double-layer protective coatings with anti-corrosion treatments. JULI® applies industry-grade surface protection processes to extend rack lifespan and maintain structural safety under long-term cold storage conditions.

Selecting the correct system depends on warehouse size, storage density, temperature levels, product turnover, and automation requirements. Options include selective pallet racking, drive-in racking, shuttle systems, or AS/RS (Automated Storage & Retrieval Systems). JULI® engineers analyze each project to recommend the most cost-effective and space-optimized racking solution.

While manual racking systems are cost-effective and flexible for small warehouses, they require more labor in cold environments, which can reduce productivity. Automated systems—such as mobile racking, pallet shuttle systems, and AS/RS—minimize human exposure to low temperatures, maximize space utilization, and significantly improve operational efficiency. JULI® provides both manual and automated racking options tailored to cold chain logistics.