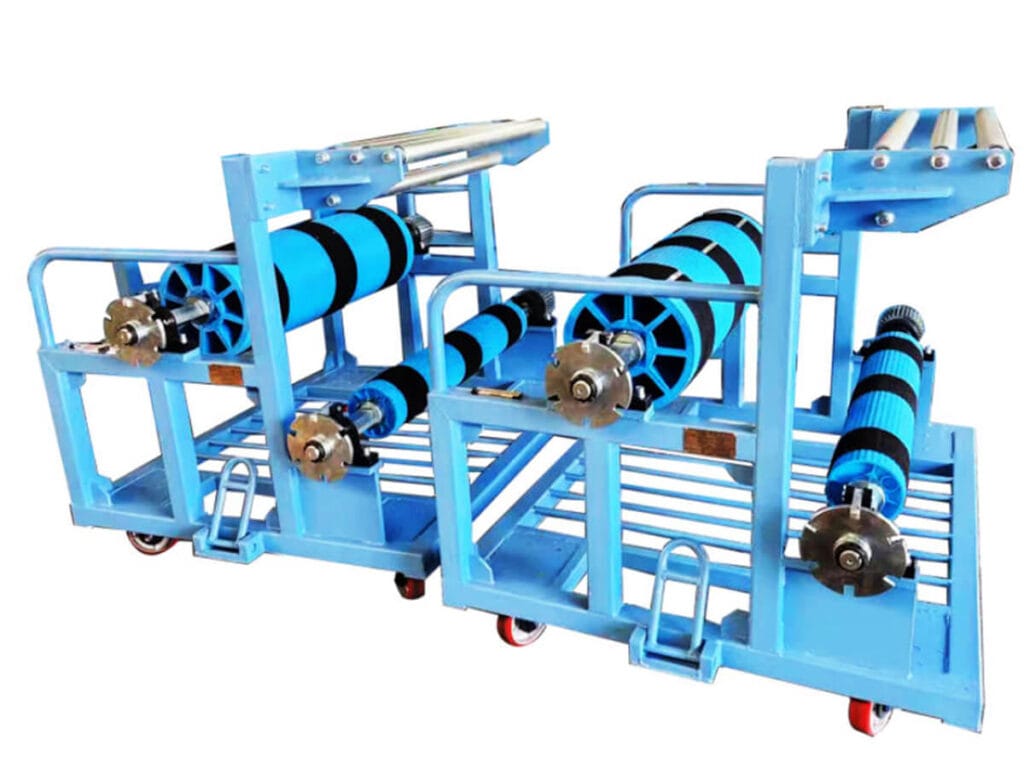

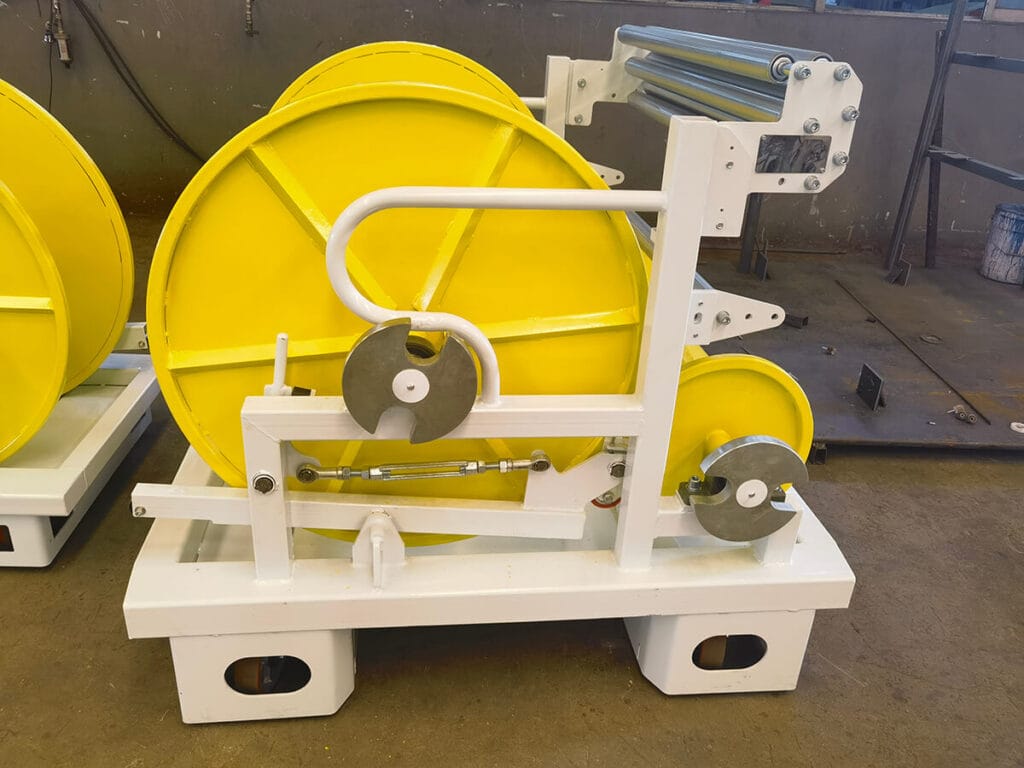

Tire Raw Material Storage Cart / Tire Component Storage Trolley

Engineered for the tire industry, our customizable storage carts streamline material handling, protect critical components, and optimize production workflow from raw material storage to final assembly.

JULI® Custom Tire Raw Material Storage Carts

The Tire Raw Material Storage Cart—also known as the Tire Component Storage Cart or Tire Production Support Trolley—is a highly efficient storage and transport solution designed for tire manufacturing workflows. Equipped to organize, store, and move essential raw materials such as cord fabric, sidewalls, belt layers, cap strips, treads, and inner liners, its optimized design greatly improves production efficiency and ensures safe, well-organized handling of materials.

All specifications for Tire Raw Material Storage Carts / Tire Component Storage Trolleys—including corrosion resistance, load capacity, number of compartments or tiers, cart type (such as open-frame carts or enclosed carts), surface treatment (such as hot-dip galvanizing or electrostatic powder coating), as well as flexible options for dimensions, caster type, compartment layout, and color—can be fully customized to meet your specific tire manufacturing and material handling requirements.

| Specification | Details (Customizable) |

|---|---|

| Frame Material | High-strength steel / composite with anti-corrosion coating |

| Load Capacity | Custom per production requirements |

| Dimensions | Fully customizable (L × W × H) |

| Mobility | 360° industrial swivel casters with brakes, high wear resistance |

| Compartments/Layers | Custom layout, typically 4–8 tiers |

| Surface Finish | Powder coating / hot-dip galvanizing |

| Extra Features | Forklift pockets, foldable design, labeling holders, guard rails |

Custom Structural Options

We offer eight structure types, each customizable in size, surface, and function:

Optimize Your Operations with JULI® Tire Raw Material Storage Carts

Whether you’re upgrading your tire manufacturing logistics or improving the efficiency and safety of raw material handling, JULI® delivers high-quality, fully customizable tire raw material storage carts designed to maximize material organization, protect sensitive components, and streamline in-plant transport.

We provide:- Custom Dimensions & Structural Designs – Tailored storage carts for organizing and transporting tire manufacturing materials such as tire cord fabric, steel belts, sidewalls, bead bundles, treads, and liners.

- OEM & Private Label Services – Build your brand with our advanced manufacturing capabilities and flexible customization options.

- Technical Support & Load Capacity Consultation – Ensure your carts meet the specific load-bearing, safety, and durability requirements of your production line.

- Fast Production & Global Shipping – Reliable manufacturing lead times and worldwide delivery to keep your operations running smoothly.

Why Choose JULI® Custom Tire Production Trolleys

Tailor-Made Excellence: Each unit is designed to your specifications—size, load capacity, compartment layout, and finish—ensuring optimal fit for your workflow.

Robust and Functional: High-quality materials and build standards deliver long-lasting performance even under demanding production conditions.

Space-Efficient & Agile: Modular, reconfigurable design allows streamlined storage, fast access, and flexible deployment across production stations.

Protects Your Assets: Carefully designed partitions and structural strength preserve the integrity of sensitive tire materials during manipulation and storage.

Global Delivery, Local Support: Expert technical consultation available to define your requirements—and we deliver worldwide.

A Tire Raw Material Storage Cart—also referred to as a Tire Component Storage Trolley—is a specialized storage and transport solution engineered for the tire manufacturing industry. It is designed to efficiently organize, protect, and transport key tire production materials such as cord fabric, steel belts, treads, sidewalls, inner liners, and belt layers between production stages. By ensuring material integrity and optimizing workflow, it plays a crucial role in improving operational efficiency and reducing downtime in tire factories.

Yes. JULI® specializes in fully customizable tire storage carts, offering flexibility in:

Dimensions & Compartment Layouts – To fit diverse raw materials and production line setups.

Frame Materials – High-strength steel or composite materials with anti-corrosion finishes.

Load Capacities – From light-duty to heavy-duty designs for bulk raw materials.

Surface Treatments – Electrostatic powder coating or hot-dip galvanizing for durability.

Caster Options – High-performance swivel or fixed casters with brake locks.

Our engineering team ensures each cart is tailored to integrate seamlessly into your production process.

Pricing is determined by cart size, material selection, compartment configuration, load capacity, and finish type. Standard designs are more cost-efficient, while fully customized carts may require a higher investment due to enhanced durability and specialized features. For an accurate quotation, we provide personalized cost assessments based on your production needs and operational goals.

Absolutely. Modular storage shelving is available in light-duty, medium-duty, and heavy-duty configurations, designed to support various load capacities. Selecting the appropriate shelving system with verified weight ratings and following manufacturer guidelines ensures safe and durable storage solutions for heavy items and industrial materials.

Proper storage is essential for preserving raw material quality. JULI® recommends:

Controlled Environment – Store materials in cool, dry, UV-protected spaces.

Material Segregation – Use dedicated compartments to avoid contamination or adhesion.

Correct Positioning – Prevent deformation by avoiding excessive stacking pressure.

Using JULI® Tire Raw Material Storage Carts not only improves handling efficiency but also extends the lifespan of sensitive tire manufacturing components.

Revolutionize Your Storage Strategy with JULI®

Contact us today to explore how JULI®’s sustainable storage solutions can enhance your operational efficiency and environmental impact.