In modern industry and logistics warehousing, the storage management of industrial commodity (such as cotton yarn, fabric rolls, natural rubber, synthetic rubber, granules, glass, PVC pipes, etc.) is a key factor in improving warehouse efficiency and reducing operational costs. JULI® provides customized industrial commodity storage racking solutions that help enterprises achieve high-density, safe, and efficient warehousing management while ensuring the integrity and quality of goods.

Solution Overview

- Heavy goods that require high load-bearing capacity of racks

- Diverse specifications requiring flexible and adjustable racking

- High safety risks such as glass breakage or particle spillage

-

Low space utilization, requiring optimized layout for higher storage density

- Palletized storage combined with high-density racking systems

- Modular and adjustable designs to fit different sizes and weights

- Safety protection designs to secure fragile or slippery goods such as glass and rubber

- Optimized workflow and path planning to improve warehouse efficiency

- Durable materials and anti-corrosion treatment to extend racking lifespan

Industry Application Scenarios

Cotton Yarn Storage

- Rack Type: Heavy-duty pallet racking or adjustable multi-tier racking.

- Features: High load capacity, flexible layer height, and excellent ventilation.

- Advantages: Prevents yarn compression or deformation, ensures easy handling, and supports accurate inventory management.

Fabric Storage

- Rack Type: Beam racking or fabric roll hanging racking.

- Features: Adjustable width and spacing, designed to fit multiple fabric sizes.

- Advantages: Maximizes warehouse space, supports manual or mechanical picking, and simplifies fabric storage operations.

Natural Rubber Storage

- Rack Type: Pallet racking or flow racking.

- Features: Moisture-proof, corrosion-resistant, and suitable for extended storage periods.

- Advantages: Extends rubber shelf life, reduces storage losses, and ensures better product preservation.

Chemical Synthetic Material Storage

- Rack Type: Enclosed racking or adjustable pallet racking.

- Features: Strong load capacity, corrosion resistance, and flexible adjustment for different synthetic materials.

- Advantages: Keeps products safe, supports long-term storage, and improves warehouse efficiency.

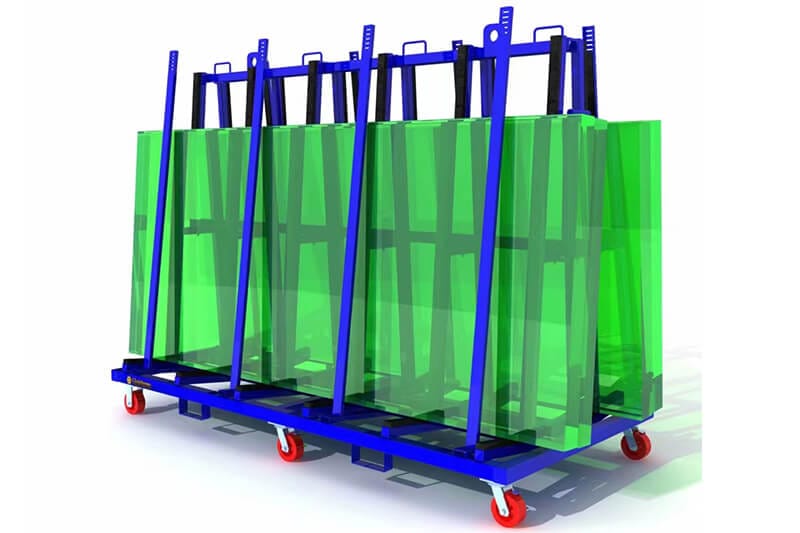

Glass Storage

- Rack Type: Anti-shock inclined racks or specialized glass standing racks.

- Features: Strong structural support, anti-shock design, and anti-slip surface.

- Advantages: Reduces breakage risk, guarantees product safety, and secures fragile glass storage.

PVC Pipe Storage

- Rack Type: Pipe racking or adjustable pallet racking.

- Features: Designed for multi-specification pipe storage and stable support.

- Advantages: Improves storage density, simplifies sorting, and enables efficient pipe handling.

JULI® Racking Product Recommendations

| Rack Type | Application Scenarios | Key Features |

|---|---|---|

| Pallet Racking | Cotton yarn, fabric, granules | High load capacity, suitable for industrial commodity storage |

| Flow Racking | Natural rubber, synthetic rubber | FIFO management, ensures product quality |

| Drive-in Racking | PVC pipes, glass | High-density storage, space-saving |

| Adjustable Racking | All industrial commodity | Flexible adjustment, fits different storage needs |

| Anti-shock Glass Racking | Glass | Anti-shock and anti-slip, reliable safety |

| Inclined / Hopper Racking | Granules | Facilitates material flow and sorting |

Solution Advantages

High Space Utilization: Optimized racking layout for high-density storage

Improved Operational Efficiency: Palletized, flow, and inclined racking enhance picking and inbound/outbound speed

High Safety: Anti-shock, anti-slip, and anti-compression designs protect both goods and operators

Strong Adaptability: Modular and adjustable racking fits different industrial commodity specifications

Low Maintenance Cost: Corrosion-resistant materials and surface treatment extend racking lifespan

Implementation Steps

Needs Analysis: On-site measurement of warehouse area, cargo size, weight, and handling frequency

Solution Design: Customized racking types, load capacity, and layout based on product characteristics

Rack Manufacturing: Production using hot-dip galvanized steel or stainless steel for durability

Installation & Testing: Installation per design, load testing, and safety inspection

Operation Training: Training for warehouse staff on safe operation and maintenance

Material & Protection Recommendations

-

Hot-dip galvanized steel: Suitable for most industrial commodity warehouses, corrosion-resistant and durable

-

Stainless steel: Ideal for high-humidity or corrosive environments

-

Anti-shock & Anti-slip Treatment: Essential for glass and fragile material storage

-

Adjustable Pallets & Support Beams: Flexible for various sizes and weights

Success Stories – Real-World Applications of Our Tire Racks

We have successfully implemented customized storage solutions for leading apparel and textile manufacturers, helping them improve material handling, protect sensitive fabrics, and streamline warehousing. Here is a recent example:

Revolutionize Your Storage Strategy with JULI®

Contact us today to explore how JULI®’s sustainable storage solutions can enhance your operational efficiency and environmental impact.